Gearbox Alignment Issues

What are the common symptoms of gearbox misalignment in industrial machinery?

Common symptoms of gearbox misalignment in industrial machinery include increased vibration, unusual noise, overheating, and accelerated wear on bearings and gears. These symptoms can lead to decreased efficiency, increased maintenance costs, and ultimately, equipment failure if not addressed promptly.

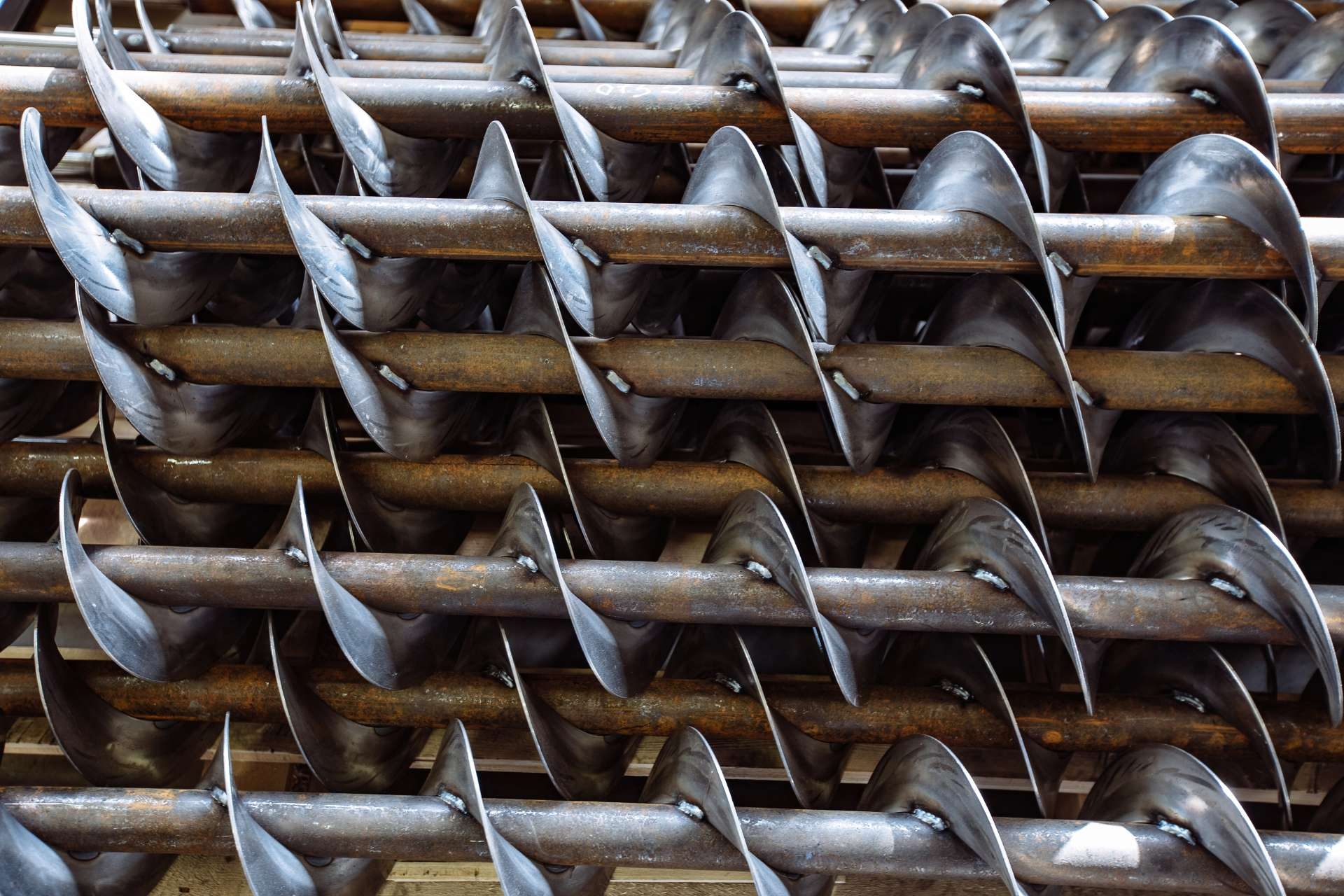

Common Signs of Wear and Tear in Extruder Gearboxes